Northwest Rubber

Overview

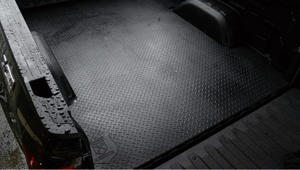

Northwest Rubber specializes in recycled rubber products. The company was founded in the 60s and focuses on various business lines like truck bed mats, fit floor mats for their fitness line, and products for farming. Northwest Rubber is looking to scale especially their newer direct-to-consumer sector. Their business is roughly a 50/50 split between D2C and retail orders.

"There are 3 core reasons we chose Smart. Their ability to automate and connect into systems, the opportunity for Smart to help us scale with their wide footprint, and all that a reasonable cost."

"There are 3 core reasons we chose Smart. Their ability to automate and connect into systems, the opportunity for Smart to help us scale with their wide footprint, and all that at a reasonable cost."

The Challenge

Northwest Rubber’s products require custom boxes and are often big and bulky. Matthew Bosco, Operations Manager, mentioned that their previous 3pl “wasn’t strong with big and bulky. It’s a lot more complicated from a shipping perspective”. Northwest Rubber also struggled with misships. Their previous 3pl had “a lot of challenges getting product packed and shipped and lost."

- A 3PL that could handle the needs of big and bulky products

- Customized packaging for bigger product

- Help handle shipments and delivery

The Solution

After vetting 3-4 fulfillment companies, Northwest Rubber chose Smart Warehousing as their nationwide fulfillment partner. “We initially switched our black armor products, and then afterward switched over the fit floor and red barn products as well”.

Ultimately, Bosco mentions that it was Smart’s “ability to automate and connect into systems and then scale and cost” that led them to partner with Smart Warehousing. With the company recently launching an eCommerce program for one line of business, partnering with Smart allowed them to meet the growing demand from new customers, while also scaling the other two lines on both retail and eCommerce. With orders scaling, they are excited about the opportunity to leverage more of Smart’s 23 warehouses to get their products to their customers faster and at a lower cost.

Using Smart’s inventory management system, SWIMS, Northwest Rubber is able to track all their outbound orders easily and also stay up to date on their current inventory levels. In fact, the partnership with Smart saves them almost 3 business days of work a month where they previously has to spend “hours figuring out misships” and are now seeing increased order accuracy.

Smart Warehousing specialized in custom shipments and all shipment sizes, making Northwest Rubber an optimal fit.